Submersible Slurry Pump

ZJQ is a single stage, single suction, single casing, submerged overhang shaft centrifugal slurry pump, designed to handle abrasive and corrosive slurries in applications such as mining and mineral processing, power plants, refining, coal preparation etc.

Inquire Now

Product Description

ZJQ is a single stage, single suction, single casing, submerged overhang shaft centrifugal slurry pump, designed to handle abrasive and corrosive slurries in applications such as mining and mineral processing, power plants, refining, coal preparation etc., providing excellent performance when dealing with corrosive slurries contain crystals.

Usage Conditions

1. The power supply is 50Hz, 380V ,60Hz,440Vthree-phase AC power.

2. The maximum temperature of the medium can not be higher than 60 ℃, the medium does not contain flammable and explosive gases.

3. The maximum weight concentration of solid particles in the medium: 45% ash, slag was 60%.

4.The unit maximum diving depth of not more than 100 meters, the minimum diving depth of not less than 1 meter.

5. Units in the medium to vertical work as well, running for the continuous operation mode.

Specifications

Flow range: 10-1450m3/h

Head range: 15-95m

The maximum diameter of solid in medium: 92mm

Model

ZJQ200-35-45

ZJQ Submersible slurry pump

200 Max.capacity in m³/hr

35 Max.head in meter

45 Max.power in kw

Typical Applications

Tailing

Thickener Drainage

Slag Mills

Magnetite Mixing

Coal

Steel Plant

Power Plant

The wet parts of ZJQ are made of high-chrome iron, the high hardness will give excellent wear life in most slurry handing applications.

Standard stainless Steel (316) is another option for the wet parts for corrosive applications.

Structure & Features

1、Pump and motor are of one-piece unit design with the impeller and motor sharing the same shaft,ensuring stable operation.

2、The pumps do not request fixed supports so can be easily moved as required.

3、A mechanical seal is used to protect the motor from contamination of slurry or liquid so the risk of motor damage will be decreased.

4、Less noise and vibration in running condition

5、Wet parts are made of high-chrome alloy or stainless steel,excellent performance to resist wear,corrosion,impact or erosion.

6、Different impeller diameters are available to suit different head requirements.

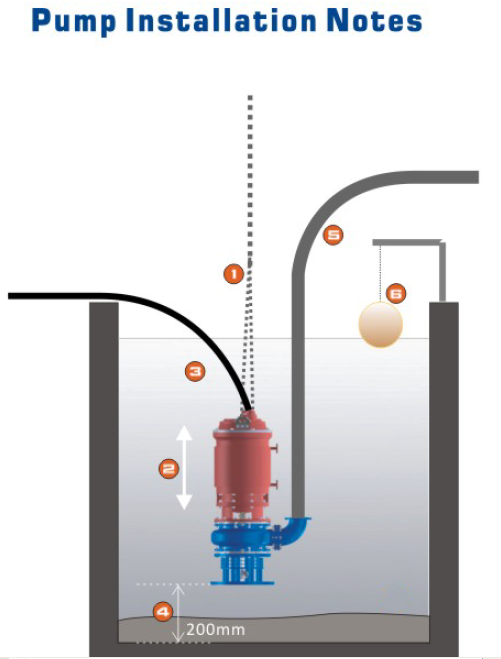

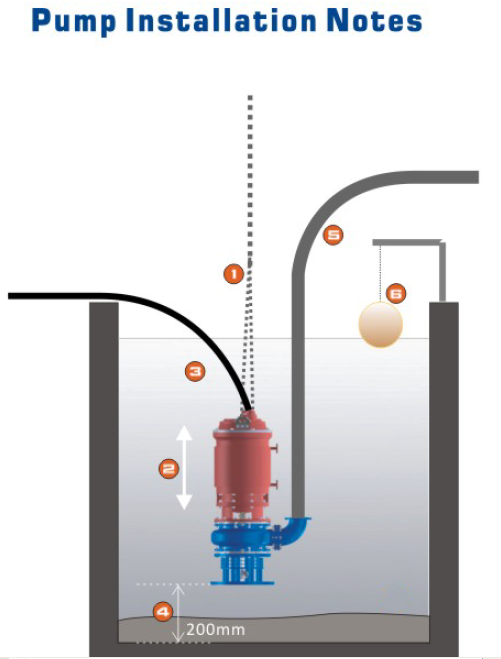

Pump Installation Notes

1、Never lift or suspend the pump by the electrical cable.

2、Ensure that the pump is suspended in a vertical position.

3、Always keep the cable away from the rotating inducer.

4、Pumps should be suspended by chains,the minimum distance between the bottom of the frame to the pit bottom is 200mm.

5、Always use appropriate flexible hose for the pump discharge pipe,do not connect the pump directly to a rigid pipe.

6、An automatic switch should be used to turn on and off the motor based on high and low level conditions,float ball or infrared systems are typical.

7、Start frequency should not exceed 20starts/hours.

8、To ensure even distribution and proper flow,a minimum liquid volume should be ensured,please contact SFP for sizing

ZJQ Performance Parameter |

No. | Model | Outlet diam. mm | Capacity m3/h | Head | Power | Speed r/min | Max.pass solid mm | Weight |

m | kW | kg |

1 | ZJQ10-10-3 | 40 | 10 | 10 | 3 | 1460 | 8 | 65 |

2 | ZJQ15-8-3 | 50 | 15 | 8 | 3 | 1460 | 10 | 65 |

3 | ZJQ10-20-4 | 40 | 15 | 22 | 4 | 1460 | 10 | 85 |

4 | ZJQ20-12-4 | 50 | 20 | 18 | 4 | 1460 | 10 | 85 |

5 | ZJQ15-15-4 | 50 | 15 | 15 | 4 | 1460 | 10 | 85 |

6 | ZJQ30-10-4 | 65 | 30 | 10 | 4 | 1460 | 10 | 85 |

7 | ZJQ20-30-5.5 | 50 | 20 | 30 | 5.5 | 1460 | 13 | 110 |

8 | ZJQ30-20-5.5 | 65 | 30 | 20 | 5.5 | 1460 | 13 | 112 |

9 | ZJQ45-15-5.5 | 80 | 45 | 15 | 5.5 | 1460 | 13 | 115 |

10 | ZJQ50-10-5.5 | 80 | 50 | 10 | 5.5 | 1460 | 13 | 120 |

11 | ZJQ30-30-7.5 | 65 | 30 | 30 | 7.5 | 1460 | 13 | 135 |

12 | ZJQ45-20-7.5 | 80 | 32 | 20 | 7.5 | 1460 | 13 | 138 |

13 | ZJQ50-16-7.5 | 80 | 45 | 15 | 7.5 | 1460 | 13 | 135 |

14 | ZJQ80-10-7.5 | 100 | 100 | 10 | 7.5 | 1460 | 21 | 135 |

15 | ZJQ40-25-11 | 80 | 40 | 25 | 11 | 1480 | 13 | 240 |

16 | ZJQ50-26-11 | 80 | 50 | 26 | 11 | 1480 | 13 | 240 |

17 | ZJQ70-20-11 | 100 | 70 | 20 | 11 | 1480 | 13 | 240 |

18 | ZJQ100-16-11 | 100 | 100 | 18 | 11 | 1480 | 21 | 240 |

19 | ZJQ35-35-15 | 80 | 25 | 40 | 15 | 1480 | 13 | 260 |

20 | ZJQ50-30-15 | 80 | 50 | 26 | 15 | 1480 | 13 | 260 |

21 | ZJQ70-25-15 | 100 | 70 | 24 | 15 | 1480 | 13 | 260 |

22 | ZJQ100-20-15 | 100 | 100 | 18 | 15 | 1480 | 21 | 270 |

23 | ZJQ120-15-15 | 100 | 150 | 15 | 15 | 1480 | 21 | 270 |

24 | ZJQ150-15-18.5 | 150 | 150 | 18 | 18.5 | 1480 | 32 | 550 |

25 | ZJQ180-12-18.5 | 150 | 200 | 12 | 18.5 | 1480 | 45 | 550 |

26 | ZJQ150-22-22 | 150 | 150 | 22 | 22 | 1480 | 32 | 600 |

27 | ZJQ250-15-22 | 150 | 200 | 15 | 22 | 1480 | 45 | 600 |

28 | ZJQ60-46-30 | 100 | 60 | 46 | 30 | 1480 | 14 | 550 |

29 | ZJQ70-38-30 | 100 | 70 | 38 | 30 | 1480 | 21 | 710 |

30 | ZJQ100-35-30 | 100 | 100 | 35 | 30 | 1480 | 21 | 710 |

31 | ZJQ120-30-30 | 150 | 120 | 30 | 30 | 1480 | 21 | 710 |

32 | ZJQ200-25-30 | 150 | 200 | 20 | 30 | 1480 | 21 | 710 |

33 | ZJQ250-20-30 | 200 | 300 | 15 | 30 | 1480 | 28 | 700 |

34 | ZJQ100-40-37 | 100 | 100 | 40 | 37 | 1480 | 21 | 850 |

35 | ZJQ250-22-37 | 200 | 250 | 22 | 37 | 1480 | 28 | 775 |

36 | ZJQ150-35-45 | 150 | 150 | 35 | 45 | 1480 | 36 | 1000 |

37 | ZJQ200-30-45 | 150 | 200 | 30 | 45 | 1480 | 36 | 1110 |

38 | ZJQ150-45-55 | 150 | 150 | 45 | 55 | 1480 | 21 | 1140 |

39 | ZJQ250-35-55 | 150 | 250 | 35 | 55 | 1480 | 36 | 1140 |

40 | ZJQ400-20-55 | 200 | 600 | 15 | 55 | 980 | 46 | 1220 |

41 | ZJQ250-45-75 | 150 | 200 | 45 | 75 | 1480 | 21 | 1540 |

42 | ZJQ200-50-75 | 150 | 200 | 50 | 75 | 1480 | 14 | 1550 |

43 | ZJQ300-35-75 | 200 | 300 | 35 | 75 | 1480 | 28 | 1550 |

44 | ZJQ400-25-75 | 200 | 400 | 25 | 75 | 1480 | 25 | 1550 |

45 | ZJQ500-20-75 | 200 | 500 | 20 | 75 | 980 | 25 | 1550 |

46 | ZJQ200-60-90 | 150 | 200 | 60 | 90 | 1480 | 14 | 1550 |

47 | ZJQ400-40-90 | 200 | 400 | 40 | 90 | 1480 | 28 | 1550 |

48 | ZJQ500-25-90 | 200 | 500 | 25 | 90 | 980 | 25 | 1550 |

49 | ZJQ400-50-110 | 200 | 400 | 50 | 110 | 1480 | 28 | 1970 |

50 | ZJQ600-30-110 | 200 | 600 | 30 | 110 | 980 | 28 | 1970 |

51 | ZJQ780-26-110 | 300 | 780 | 26 | 110 | 980 | 50 | 1970 |

52 | ZJQ400-60-132 | 200 | 400 | 60 | 132 | 1480 | 28 | 2000 |

53 | ZJQ500-45-132 | 200 | 500 | 45 | 132 | 980 | 28 | 2500 |

54 | ZJQ500-55-132 | 200 | 500 | 55 | 132 | 980 | 28 | 2500 |

55 | ZJQ800-35-132 | 300 | 800 | 35 | 132 | 980 | 42 | 2700 |

56 | ZJQ1000-22-132 | 300 | 1000 | 22 | 132 | 980 | 50 | 3200 |

57 | ZJQ650-52-160 | 200 | 650 | 52 | 160 | 980 | 28 | 3300 |

58 | ZJQ780-50-185 | 300 | 780 | 50 | 185 | 980 | 38 | 3500 |

59 | ZJQ800-55-220 | 300 | 800 | 55 | 220 | 980 | 38 | 3700 |

60 | ZJQ1250-35-220 | 350 | 1250 | 35 | 220 | 740 | 45 | 4200 |

61 | ZJQ1750-30-250 | 350 | 1750 | 30 | 250 | 740 | 55 | 4500 |

62 | ZJQ1500-35-250 | 350 | 1500 | 35 | 250 | 740 | 50 | 4700 |

63 | ZJQ2000-35-315 | 400 | 2000 | 35 | 315 | 740 | 60 | 5500 |