Performance Parameter

No. | Model | CLEAR WATER PERFORMANCE |

Allowable Max. Power | Capacity | Head | Speed | Efficiency | NPSH | Impeller diameter |

(kw) | m3/h | L/s | H(m) | (r/min) | η% | (m) | (mm) |

1 | SF-1.5/1B-AH(R) | 15 | 3.5-28.8 | 1.2-8 | 6-68 | 1200-3800 | 40 | 2.0-4.1 | 152 |

2 | SF-2/1.5B- AH(R) | 15 | 12.4-72 | 3.3-20 | 6-58 | 1200-3200 | 45 | 3.5-8 | 184 |

3 | SF-3/2C- AH(R) | 30 | 21.6-86.4 | 6.1-24 | 12-64 | 1300-2700 | 55 | 4.0-6.0 | 214 |

4 | SF-4/3C- AH(R) | 30 | 86.4-198 | 24-55 | 9-52 | 1000-2200 | 71 | 4.0-6.0 | 245 |

5 | SF-4/3D- AH(R) | 60 | 86.4-198 | 24-55 | 9-52 | 1000-2200 | 71 | 4.0-6.0 | 245 |

6 | SF-6/4D- AH(R) | 60 | 162-335 | 40-93 | 12-56 | 800-1550 | 65 | 5.0-8.0 | 365 |

7 | SF-6/4E- AH(R) | 120 | 162-385 | 40-106 | 12-64 | 800-1550 | 65 | 5.0-8.0 | 365 |

8 | SF-10/8E-M | 120 | 666-1440 | 185-400 | 14-60 | 600-900 | 73 | 4-9.8 | 549 |

9 | SF-8/6R- AH(R) | 300 | 360-828 | 100-230 | 10-61 | 900-1140 | 72 | 2.0-9.0 | 510 |

10 | SF-8/6E- AH(R) | 120 | 126-720 | 35-180 | 10-58 | 500-1100 | 72 | 2.0-9.0 | 510 |

11 | SF-10/8R- M-SF | 300 | 666-1440 | 185-400 | 14-60 | 600-1100 | 70 | 4.5-8 | 549 |

12 | SF-10/8ST- AH(R) | 560 | 612-1368 | 170-380 | 11-61 | 400-850 | 71 | 4.0-10 | 686 |

13 | SF-12/10ST- AH(R) | 560 | 936-1980 | 260-550 | 7-68 | 300-800 | 82 | 2.5-7.5 | 762 |

14 | SF-14/12ST- AH(R) | 560 | 1260-2772 | 350-770 | 13-63 | 300-600 | 77 | 3.0-10 | 965 |

15 | SF-16/14TU- AH(R) | 1200 | 1368-3060 | 380-850 | 11-63 | 250-550 | 79 | 4.0-10 | 1067 |

16 | SF-20/18TU- AH(R) | 1200 | 2520-5400 | 700-1500 | 13-57 | 200-400 | 85 | 5.0-10 | 1370 |

Product features

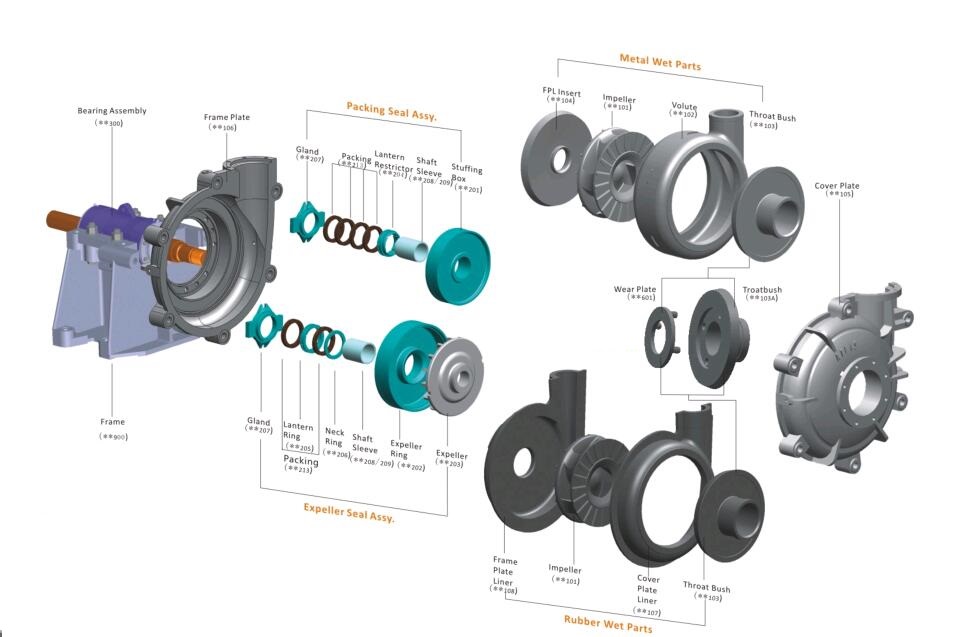

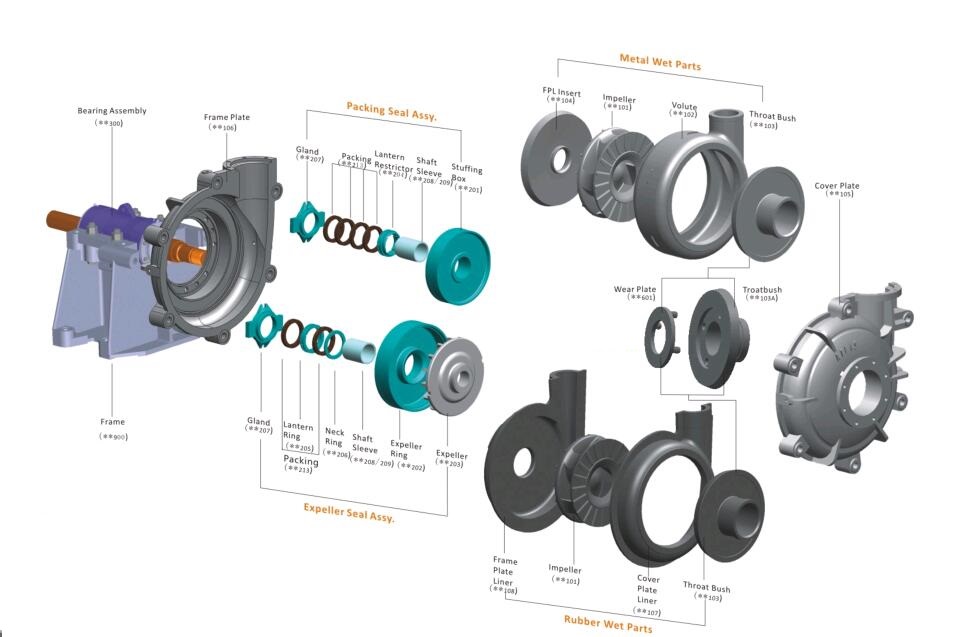

1、This series of pumps are horizontal, vertical, double pump shell structure, pump body and pump cover with a replaceable metal or rubber lining, the lining can be always used till wear out, lined with replaceable, prolong maintenance cycle, reduce the operation cost.

2、Pump outlet direction is available in 8 different rotational angle selections.

3、Bearing components are cylinder structure, easy to adjust the interval between impeller and front liner, easy access maintenance. Grease lubricated bearing assembly.

4、 Pump shaft seals include packing seal, impeller seal and mechanical seal.

5、 Wide range of pump performance, good cavitation performance and high efficiency. Multistage tandem technology can be used to meet the long-distance transport.

6、Transmission types v-belt, elastic coupling, gear reducer, fluid coupling, variable frequency and thyristor speed control etc. The v-belt transmission with DC, DCZ, CV, CVZ, CR, CRZ, ZVZ transmission.

7、Flow components are available in a variety of wear-resistant metal or rubber material selection

8、Variable speed and configuration modes, under best operating condition. High efficiency with long service life, good pump performance under rough service condition.

Pump Structure

Application Range

Mainly convey various concentrations of abrasive slurry or corrosive slurry, is an ideal product to slurry transportation

Application Range |

Iron Ore | Copper | Alumina | Gold | Silver | Wolfram | Tin |

Coal | Steel | Electric Utilities | Titanium | Lead & Zinc | Molybdenum | Bauxite |

Oil Shale | Chemical industry | Potash | Phosphate | Chemical Fertilizer | Asbestos | Tobacco |

Sand & Gravel | Mineral Sands | Cement | Building Products | Paper & Pulp | Water & Sewage Treatment | Sugar |

Application Examples

Mine: Black, non-ferrous ore slurry material pump and all kinds of concentrate and tailings conveying

Metallurgy: Transport various slurry for aluminium or steel manufacture

Coal: Coal mining, washing and various coarse and fine coal slurry transportation

Electricity: Remove power plant ash, wash ash, various ash dregs or ash slurry transportation

Construction materials: Various mud sand slurry(such as Cement slurry) transportation

Chemical: Phosphatic fertilizer or potassic fertilizer factory various abrasive slurry transportation

Water conservancy: Lake, river dredge, sediment, grit, High plastic clay Suction line to transportation

Material Form

Material code | Material brand | HardnessHRC | Special Performance | Application |

A05 | KmTBCr26 | ≥56 | Scour resistance is a little bit lower than A07 with certain corrosive resistance | Used for higher wear condition with PH between 5 and 12 |

A07 | KmTBCr15Mo3 | ≥59 | Best scour resistance but lower wear resistance than A05 | Used for higher scour and shock condition |

A01 | KmTBCr8 | ≥55 | The scour resistance is about 0.9times of A05 | Used for mud pump and ash pump |

A11 | KmTBMnMo | 38-42 | Lighter scour resistance and lower hardness.it can be perforated and tapped | Used for light wear conditon with fine grain |

A49 |

| ≥43 | It has certain scour resistance and corrosive resistance in low PH condition.Its wear resistance is simillar with A03 | Used for low PH condition especially for gas and low-sour condition.PH≥4 anti-acid desulphurization equipment |

A33 |

| ≥35 | It has certen scour resistance,and similar with A03.Also has certain corrosive resistace | Used for conveying a PH≥1 oxidation pulp.Such as transmission of phosphate fertilizer plant phosphorus gypsum and nitric acid, sulfuric acid, phosphate, etc |

AT12 |

| ≥62 | Higher abrasion-resistant performance than AT05;fair corrosion-resistant performance;suitable for media with PH rate is 6-14,where AT05 is not suitable | High abrasive slurry with fine particles |

AT61 |

| 63-68 | Optimized abrasion-resistant performance than AT12 | High abrasive slurry with fine particles |

Type | Material Code | Special Performance | Application |

Natural Rubber | R55 | Because of the hardness and elasticity is better than metal performance.Wear resistant,corrosive resistant and scour resistant is higher than metal material, The disadvantage is that natural rubber not scratch when using | Good wear resistant and corrosive resistant always used to desulfuration pump.tailings convey,fine grain and no sharp edge pulp. This material often make casing. |

R24 | Because of the hardness and elasticity is better than metal performance.Wear resistant,corrosive resistant and scour resistant is higher than metal material, The disadvantage is that natural rubber not scratch when using | Good wear resistant and corrosive resistant always used to desulfuration pump.tailings convey,fine grain and no sharp edge pulp. This material often make impeller. |

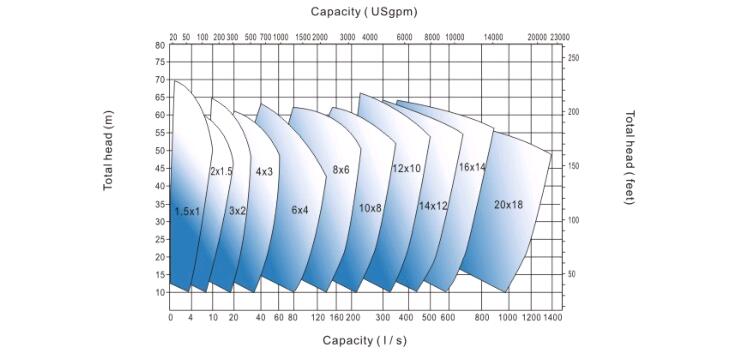

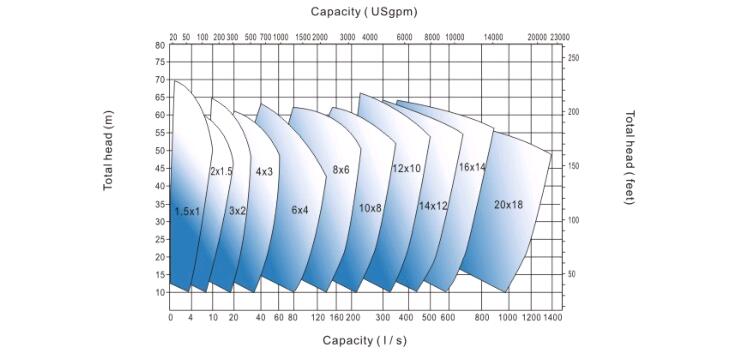

Performance Chart